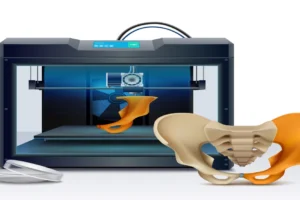

Future implant that could seamlessly be used in your individual anatomy to provide maximum functionality and comfort: a true dream of possibilities coming alive with 3D printing in healthcare.

Beyond One-Size-Fits-All: The Advantages of Customized Implants

Traditional implants often come in standardized sizes, which can lead to:

- Poor Fit: Generic implants may not perfectly match a patient’s anatomy, causing discomfort, instability, and potential implant rejection.

- Limited Functionality: A less-than-ideal fit can restrict movement and reduce the implant’s effectiveness.

- Complex Surgeries: Surgeons may need to adapt procedures to fit off-the-shelf implants, potentially increasing surgical time and risks.

3D Printing: Ushering in a New Era of Personalized Implants

3D printing offers a revolutionary solution:

- Customization: Medical imaging data like CT scans is used to create a digital 3D model of a patient’s bone structure. This model serves as the blueprint for a perfectly tailored implant.

- Improved Fit and Function: Customized implants seamlessly integrate with a patient’s anatomy, maximizing stability, comfort, and range of motion.

- Reduced Surgical Time and Risk: Pre-designed implants minimize the need for intraoperative adjustments, potentially leading to shorter surgeries and faster recovery times.

Materials that Matter: Engineering Implants for Performance

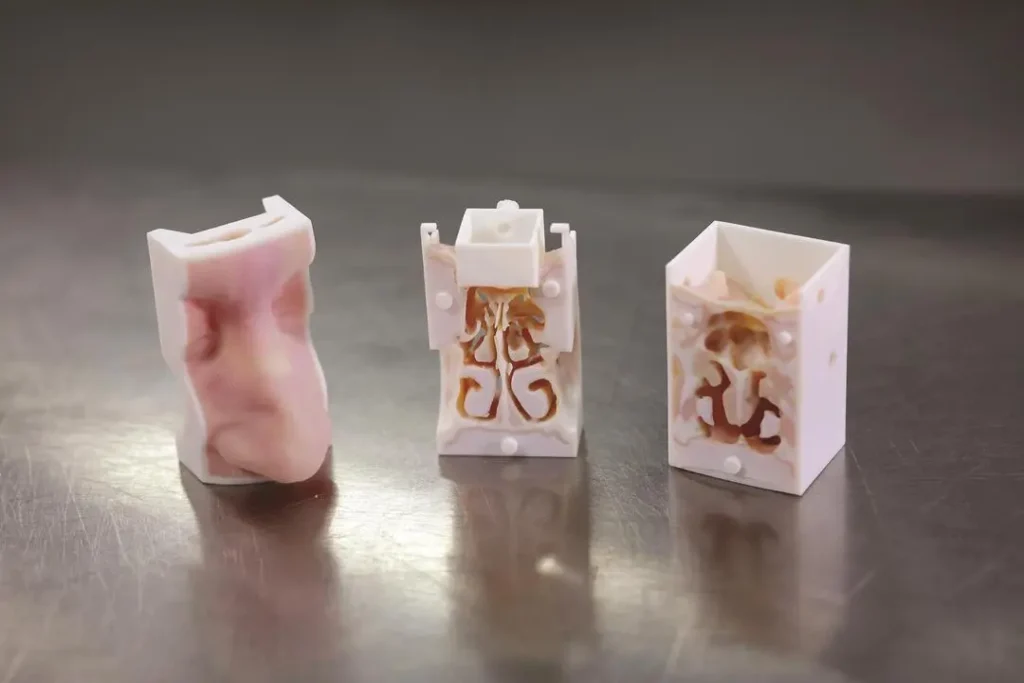

The choice of material for 3D printed implants is crucial. Biocompatible materials like:

- Titanium: Offers excellent strength, durability, and biocompatibility, making it ideal for load-bearing implants like knee and hip replacements.

- Polymers: Provide flexibility and are suitable for specific applications like facial implants or spacers.

A Glimpse into the Future: Advancements in 3D Printing Technology

The future of 3D printed implants is exciting:

- Bioprinting: Researchers are exploring the use of bioprinting to create implants with living cells and tissues, potentially leading to even better integration with the body.

- Advanced Materials: Development of new materials with improved properties like enhanced bone osseointegration (fusion with bone) is ongoing.

Precision Engineering for a Healthier You

3D printing is transforming the field of orthopedic surgery by enabling the creation of customized patient implants. These innovative solutions offer patients a new level of personalized care, promoting improved function, faster recovery, and a brighter future in healthcare.

Looking to learn more about 3D printed implants?

Search for terms like “3D printed knee replacements” or “3D bioprinting in medicine” to delve deeper into this groundbreaking technology. Check our website for further details Cure with 3D.