This isn’t a futuristic fantasy – it’s the reality of 3D printed surgical guides! These innovative tools are transforming surgeries by offering unprecedented levels of precision and customization. Let’s delve into the fascinating journey of a 3D printed surgical guide, from initial concept to its vital role in the operating room.

The Genesis: Planning and Design

The adventure begins with meticulous planning. Surgeons collaborate with radiologists, using CT scans or X-rays to create a digital 3D model of the patient’s anatomy. This model serves as the foundation for the surgical guide.

Software Takes Center Stage

Specialized software comes into play. Here, surgeons leverage their expertise to design the guide. This may involve incorporating features like drill sleeves for precise angulation or cutouts for optimal visualization during surgery.

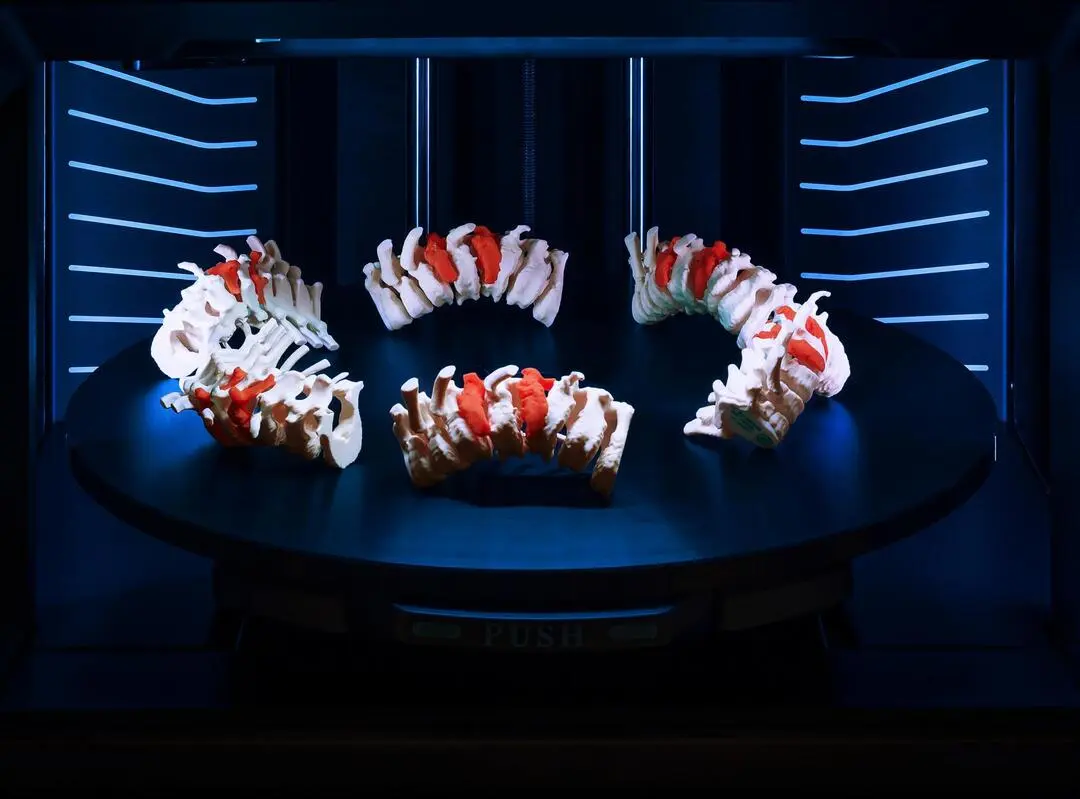

The Printing Process: Precision in Every Layer

With the design finalized, it’s time for the 3D printer to work its magic. Biocompatible resins, chosen for their safety and strength, are meticulously deposited layer by layer, bringing the digital guide to life.

Post-Processing: The Finishing Touches

Fresh out of the printer, the guide requires post-processing. This may involve cleaning, removing support structures, and curing the resin to ensure optimal strength and sterility.

Sterilization: Ensuring Patient Safety

Before entering the operating room, the guide undergoes a rigorous sterilization process. This eliminates any potential for infection, guaranteeing patient safety during surgery.

The Guide in Action: A Surgeon’s Ally

Finally, the 3D printed guide arrives in the operating room. It serves as an invaluable asset, guiding surgeons with:

- Precise Tool Placement: Drill sleeves ensure accurate drilling for implant placement or bone osteotomies.

- Enhanced Visualization: Cutouts in the guide offer a clear view of the surgical target area.

- Improved Efficiency: Streamlined procedures translate to shorter surgery times and potentially faster recovery for patients.

The Future of 3D Printed Surgical Guides

The journey doesn’t end here. The future of 3D printed surgical guides is brimming with possibilities. Researchers are exploring the use of even more advanced materials and integrating these guides with augmented reality for real-time surgical navigation.

3D Printed Surgical Guides: Revolutionizing Surgical Care

By offering unparalleled precision, customization, and efficiency, 3D printed surgical guides are transforming the landscape of surgery. These innovative tools empower surgeons to deliver exceptional patient care, paving the way for a brighter future in healthcare.