Healthcare Uses

Healthcare Specialties with maximum 3D utilization

Applications of 3D Printing in Healthcare

Introduction

3D printing is a transformative manufacturing technique that creates three-dimensional objects by adding material layer by layer. These objects are first designed on a computer using CAD (Computer-Aided Design) software. Then, advanced hardware known as a 3D printer brings the design to life.

This technology has revolutionized various industries, including aviation, fashion, and automotive. Now, it’s making significant strides in healthcare as well.

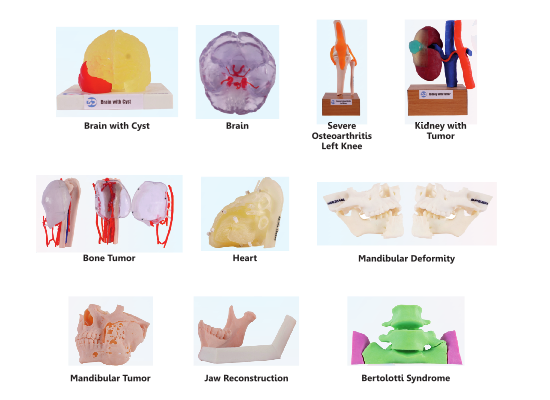

3D Printed Anatomical Bio-Models

Anatomical 3D printed models offer a powerful tool for visualizing and understanding complex anatomical structures. This technology supports:

- Pre-surgical planning: Surgeons can create precise 3D models of a patient’s anatomy, allowing for meticulous preoperative planning of complex surgeries.

- Surgical training: Realistic 3D models provide surgeons and medical students with hands-on training opportunities before performing actual procedures.

- Patient education: These models can be used to educate patients about their specific disease or complex medical condition in a clear and engaging way.

By enhancing visualization, 3D printing plays a crucial role in improving surgical planning, training, and patient understanding.

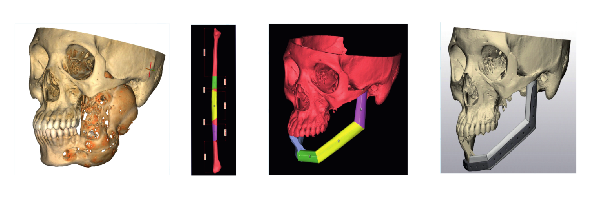

Implants Prototyping Using 3D Printing

3D printing prototyping offers a transformative approach to surgical preparation. This process allows for the rapid and accurate creation of anatomical replicas directly from a patient’s CT or MRI scan data. These replicas provide:

- Enhanced Pre-Surgical Planning: Surgeons can utilize 3D models to meticulously plan complex surgeries, leading to improved precision and efficiency.

- Superior 3D Visualization: The models enable surgeons to visualize intricate anatomical structures, fostering a deeper understanding of the surgical field.

By combining speed, accuracy, and superior visualization, 3D printing prototyping revolutionizes surgical preparation, leading to potentially better outcomes.

Patients Specific Implants

3D printing unlocks a new era of medical innovation by enabling the design and printing of customized implants. This technology offers unparalleled advantages:

- Material Choice and Strength: We can select the optimal metal type and strength for each implant, ensuring perfect compatibility and functionality within the body.

- Infinite Design Flexibility: Unlike traditional manufacturing, 3D printing allows for limitless design variations, catering to unique patient needs.

- Exceptional Accuracy: The process delivers exceptional accuracy, guaranteeing a precise fit for each implant.

By combining material choice, design freedom, and exceptional accuracy, 3D printing revolutionizes the creation of patient-specific implants.

Custom Jigs, Cutting and Drilling Guides

In complex surgeries involving tumors, arthroplasty, or deformity correction, precise bone cuts are critical for success. 3D printing technology is transforming this aspect of surgery by enabling the creation of:

- Customized Cutting Guides: Based on a patient’s CT and MRI scan data, these guides are designed to match their unique anatomy.

- Enhanced Surgical Precision: 3D-printed cutting guides ensure precise, reliable, and consistent bone cuts, significantly improving surgical accuracy.

- Bone Preservation: Precise cuts minimize unnecessary bone removal, promoting faster healing and potential long-term benefits.

- Reduced X-Rays: The guides minimize the need for intra-operative X-rays, reducing radiation exposure for both patients and medical staff.

- Shorter Surgery Times: Increased surgical accuracy leads to faster procedures, minimizing patient discomfort and potential complications.

By offering these advantages, 3D-printed cutting guides are revolutionizing surgical precision, paving the way for improved surgical outcomes.