This isn’t a futuristic fantasy – it’s the reality of 3D printed surgical guides! These innovative tools are transforming surgeries by offering unprecedented levels of precision and customization. Let’s delve into the fascinating journey of a 3D printed surgical guide, from initial concept to its vital role in the operating room.

The advent of 3D printing technology has significantly transformed various fields, with the medical domain experiencing some of the most profound advancements. Within the realm of surgery, 3D printing has emerged as a crucial tool, particularly through the development of 3D printed surgical guides. These guides are designed to enhance the precision of surgical procedures, providing tailored solutions that cater to individual patient anatomies.

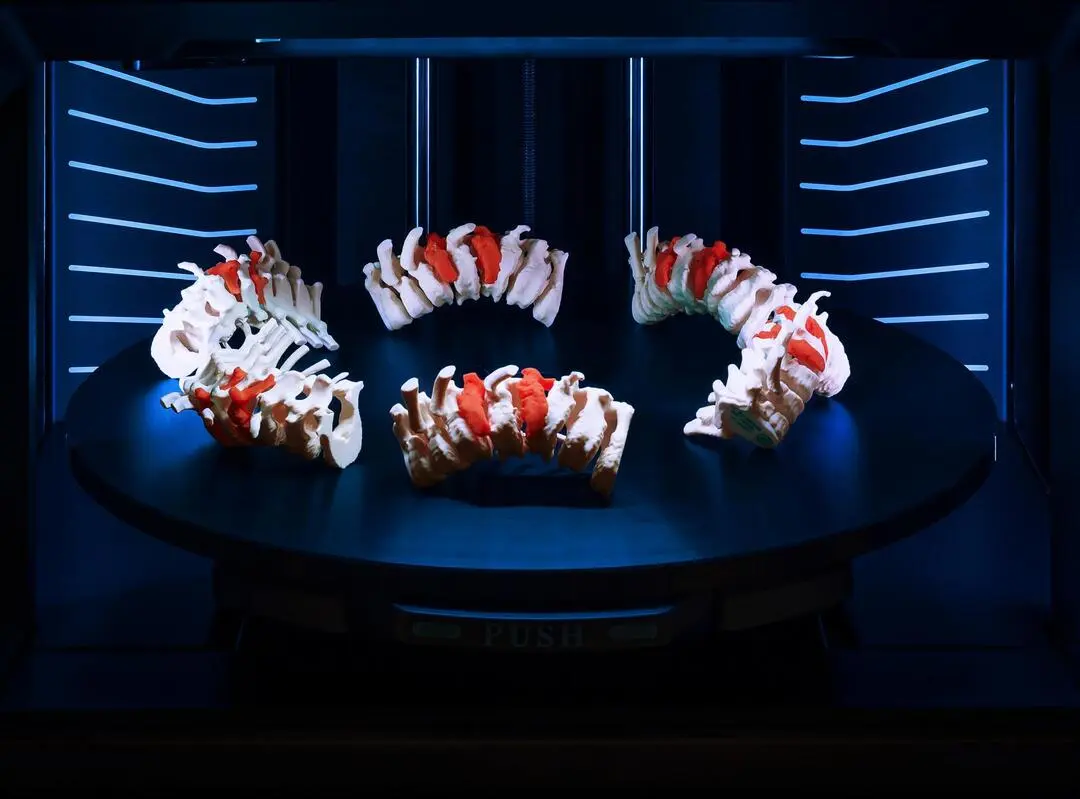

Historically, the applications of 3D printing in healthcare began with bioprinting simple anatomical models for educational purposes. Over the years, this technology has evolved, allowing for the fabrication of highly intricate components essential for surgical interventions. Surgeons can now create 3D printed models that replicate the unique characteristics of a patient’s anatomy, which assists in planning and executing complex surgeries with greater accuracy.

One of the most compelling aspects of 3D printed surgical guides is their ability to facilitate personalized surgery. Traditional surgical methods often rely on standard instruments that may not suit every individual’s unique anatomical structure. However, with the rise of additive manufacturing techniques, surgeons can produce customized guides that align precisely with the patient’s requirements. This degree of personalization not only enhances surgical outcomes but also reduces operative time, minimizes complications, and ultimately leads to improved recovery rates.

Furthermore, the integration of 3D printing into surgical practices supports the growing emphasis on precision medicine. By utilizing patient-specific data obtained from imaging technologies, such as CT scans and MRIs, medical professionals can create bespoke surgical guides that improve the overall effectiveness and safety of the surgery. This represents a significant advancement in surgical innovation, indicating a future where 3D printing will play a pivotal role in shaping the medical landscape.

Table of Contents

The Genesis: Planning and Design

Precise planning initiates the procedure. The surgeons coordinate with radiologists to develop a virtual 3D model of the patient’s anatomy by using a CT scan or X-rays. A surgical guide is then constructed from this model.

Understanding Surgical Guides: What Are They?

Surgical guides are advanced tools that assist healthcare professionals in performing precise and accurate surgical procedures. These guides come in various forms, tailored to the specific requirements of different surgical specialties, including orthopedics, dentistry, and neurosurgery. The primary function of a surgical guide is to aid surgeons by providing an anatomical reference point, thereby improving the overall efficiency and effectiveness of a surgical operation.

In the realm of orthodontics and dental surgery, for instance, surgical guides are crucial for implementing dental implant placements. Traditional methods may rely heavily on the surgeon’s skill and experience; however, 3D printed surgical guides offer a novel approach by ensuring that the implants are placed with enhanced accuracy. These guides are created from digital scans of the patient’s anatomy, allowing the fabrication of structures that perfectly adhere to individual anatomical configurations.

Orthopedic surgeries also greatly benefit from the use of surgical guides. Surgeons utilize these guides during joint reconstructive procedures, ensuring that cuts and placements are made with the greatest precision. By creating a clear pathway for instrumentation, surgical guides reduce the risk of complications and promote quicker healing times for patients. In complex procedures, such as craniofacial surgery, customized surgical guides help in defining critical landmarks, thereby increasing the likelihood of optimal outcomes.

Overall, the versatile application of surgical guides enhances not only the accuracy of surgical interventions but also significantly contributes to patient safety and recovery. Their role in the surgical field continues to evolve, especially with advancements in technology. The integration of 3D printing further revolutionizes the development of these guides, offering personalized solutions that facilitate successful surgeries across various medical disciplines.

The Design Process: From Idea to Digital Model

The initial stages of creating 3D printed surgical guides are pivotal, as they lay the foundation for successful surgical outcomes. The design process begins with collaboration among surgeons, medical professionals, and engineers, who work together to ensure that the guides are tailored to meet the unique anatomical needs of each patient. This collaborative effort merges clinical expertise with advanced engineering techniques, ultimately resulting in a precise digital model that accurately reflects an individual’s anatomy.

To commence the design process, medical imaging technologies such as CT (computed tomography) or MRI (magnetic resonance imaging) scans are utilized. These imaging modalities provide highly detailed images of the patient’s internal structures, enabling a thorough assessment of the area requiring intervention. The acquired images are then converted into a three-dimensional digital model, which accurately represents the specific anatomical features of the patient. This model serves as a crucial reference point for the subsequent phases of design and development.

Once the initial digital model is created, a series of adjustments and enhancements occur. Surgeons often provide input to fine-tune the guide based on their surgical approach and preferences. Engaging in a cyclical feedback process ensures the 3D printed surgical guides are not only functional but also align with the surgeon’s operative techniques. This tailored design is essential, as it supports the surgeon in achieving precise placement and minimizing patient trauma during procedures.

The successful attainment of a comprehensive digital model encapsulates the essence of the collaboration between various disciplines in the medical field. This synergy is critical, as it allows for the personalization of surgical guides, which in turn can lead to improved surgical precision and patient outcomes. Ultimately, as the design evolves from a conceptual idea to a detailed digital entity, it sets the stage for the subsequent phases of implementation and fabrication, marking a significant step in the journey of 3D printed surgical guides.

Material Selection: Choosing the Right Components

In the realm of 3D printed surgical guides, the selection of appropriate materials is crucial for ensuring both the functionality and safety of these devices in surgical environments. Various materials are utilized in 3D printing, each possessing unique properties that can affect the performance of surgical guides. The primary consideration in this selection process is biocompatibility, which refers to the material’s ability to interact safely with human tissues without eliciting adverse reactions.

Commonly used biocompatible materials for 3D printed surgical guides include polylactic acid (PLA), polyether ether ketone (PEEK), and medical-grade titanium. PLA is favored for its biodegradability and ease of use in 3D printing, making it a cost-effective option for temporary surgical guides. However, its mechanical strength may not be sufficient for complex surgical procedures. On the other hand, PEEK offers a remarkable balance of strength and biocompatibility, making it suitable for permanent implants; it can withstand the rigors of surgical environments while remaining inert to biological fluids.

Medical-grade titanium serves as another prevalent choice due to its exceptional strength, lightweight nature, and resistance to corrosion. Its compatibility with human tissue makes titanium an ideal material for durable and long-lasting surgical guides that may also be utilized in implant surgeries. When creating 3D printed surgical guides, it is essential to consider factors such as sterilization methods, the anticipated load during surgical procedures, and the guide’s interaction with surrounding tissues. The chosen material must endure the sterile conditions of an operating room while ensuring the accuracy and precision necessary for successful surgical outcomes.

Ultimately, the material selection process for 3D printed surgical guides is not merely a technical decision but a pivotal element in enhancing patient safety and surgical efficacy. Each material’s distinct properties will influence the design and application, emphasizing the need for careful consideration in this critical phase.

Software Takes Center Stage

And that is where the surgeon’s know-how plays out. He designs his guide. The designer will then add drill sleeves for more accurate angulation or holes for better visualization in the surgical process.

3D Printing Process: From Digital Model to Physical Guide

The journey of 3D printed surgical guides begins with a digital model, which is crafted using advanced imaging techniques such as computed tomography (CT) or magnetic resonance imaging (MRI). This digital representation captures the intricate details of the patient’s anatomy and serves as the foundation for the surgical guide. Once a precise model is generated, the file is prepared for 3D printing through specialized software that slices the model into thin horizontal layers, allowing the printer to recreate each layer sequentially.

Several printing technologies can be employed in the production of surgical guides, with the most common being Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS). FDM works by extruding melted thermoplastic material through a nozzle, while SLA utilizes a laser to cure liquid resin layer by layer. On the other hand, SLS employs a focused laser beam to sinter powdered materials, creating a solid structure. Each of these methodologies offers unique advantages in terms of precision, material properties, and production speed, enabling surgeons to select the most suitable option based on clinical requirements.

After the initial printing, post-processing is essential to optimize the usability and performance of the 3D printed surgical guides. This may involve removing support structures, cleaning the surface, and curing or strengthening the guide using additional techniques. The effectiveness of a surgical guide is largely determined by its fit and stability, both of which can be enhanced through meticulous post-processing practices. Sometimes, additional surface treatments are also applied to improve biocompatibility, ensuring that the guide functions seamlessly during surgical procedures. Ultimately, this detailed approach to the 3D printing process facilitates the creation of surgical guides that are tailored to meet the nuanced demands of specific interventions, thereby supporting successful surgical outcomes.

Testing and Validation: Ensuring Safety and Efficacy

The process of testing and validating 3D printed surgical guides is essential to ensure the safety and efficacy of these innovative tools in surgical procedures. With the increasing reliance on 3D printing technology in the medical field, it becomes imperative to establish robust protocols that govern the development of these guides from initial design to clinical application.

First, the materials used for creating surgical guides are rigorously evaluated for biocompatibility and mechanical properties. It is crucial that the chosen materials can withstand the physical demands of surgery while remaining safe for patients. Standardized tests, such as tensile strength and impact resistance assessments, provide insights into how the guides will perform under operational conditions. Following material testing, production processes are evaluated to ensure consistency. This includes verifying the accuracy of the 3D printers and assessing the quality of the prints through dimensional accuracy checks.

Subsequently, the surgical guides undergo preclinical trials. These trials typically utilize phantom models that simulate the human anatomy. By assessing the fit and function of the guides in these models, developers can gather critical data on their effectiveness in guiding surgical instruments accurately. Comprehensive radiological examinations are also performed to determine the alignment and placement of the guides in relation to anatomical landmarks.

Each 3D printed surgical guide must meet specific regulatory standards, such as those set by the FDA or other relevant health authorities. This often involves submitting detailed documentation that outlines the design process, testing protocols, and outcomes, ensuring transparency and accountability in the development of surgical aids. Furthermore, ongoing post-market surveillance after clinical use is crucial for continual assessment of the guides’ performance and safety.

Establishing a thorough testing and validation framework is fundamental in ensuring that 3D printed surgical guides can be relied upon during complex surgical procedures, ultimately enhancing patient outcomes and supporting advancing surgical practices.

The Printing Process: Precision in Every Layer

Once the design is made, it is now time for the 3D printer to work its magic. Biocompatible resins, selected because of safety and strength, will be put down layer by layer to bring that virtual guide to real life.

Post-Processing: The Finishing Touches

The guide prints fresh from the printer but then must be post-processed. This can involve clean-up, wiping away support structures, and curing the resin to achieve optimum strength and sterility.

Sterilization: Ensuring Patient Safety

The guide is thus subjected to very intense sterilization before it can be sent into the operating room. Anything that might have even the slightest possibility of allowing infection is rendered to such a high degree not possible; therefore, patient safety is assured during surgery.

Integration into Surgical Workflow: How They Are Used in Practice

The integration of 3D printed surgical guides into the surgical workflow represents a significant advancement in the field of surgery. These guides are custom-made from patient-specific data, ensuring that they fit the anatomical nuances of the individual undergoing surgery. This tailor-made approach allows for enhanced precision during procedures, ultimately translating into improved patient outcomes.

In practice, the use of 3D printed surgical guides begins during the preoperative phase. Surgeons, along with a multidisciplinary team that typically includes radiologists, orthopedic specialists, and surgical technologists, collaborate to create a precise virtual model of the patient’s anatomy. This model is then utilized to design the surgical guide, which is produced using advanced 3D printing techniques. The process emphasizes the importance of teamwork in ensuring that the guide meets the specific surgical requirements, facilitating a successful procedure.

Once in the operating room, the surgical guides play a pivotal role. They provide a template that assists surgeons in positioning instruments and implants with greater accuracy. This is particularly beneficial in complex surgeries, such as orthopedic or craniofacial procedures, where every millimeter counts. The clear visual indicators on the guides help reduce the risk of errors and allow for a smoother workflow, as surgeons can execute their techniques with enhanced confidence.

Additionally, the implementation of 3D printed surgical guides contributes to time efficiency during operations. By streamlining surgical procedures, the guides can shorten overall operation time and minimize complications, which in turn benefits recovery times for patients. As the surgical landscape continues to evolve with technological advancements, the ongoing integration of these innovative tools heralds a new era in surgical practice.

The Guide in Action: A Surgeon’s Ally

Finally, it reaches the operating room as a 3D printed guide. It can be an indispensable tool for surgeons because of its very effective assistance in the following manner:

- Precise Tool Placement: Drill sleeves aid in precise drilling for implant placement or bone osteotomies.

- Enhanced Visualization: Cutouts in the guide are provided which clear up the view of the surgical target area.

- Improved Efficiency: It ensures streamlined procedures, thereby surgery timing is minimized and saves time for potential future recovery of the patient.

Case Studies: Success Stories from the Operating Room

As the integration of technology in medicine progresses, 3D printed surgical guides demonstrate their substantial impact on surgical outcomes. Various case studies across different medical specialties highlight the efficacy of these innovative tools. For instance, one remarkable case involved a complex orthopedic procedure where a 3D printed surgical guide was utilized to assist in the precise placement of implants. By providing a tailored fit, the guide minimized surgical time and enhanced post-operative recovery for the patient, showcasing the significant advantages of personalized medical solutions.

Another compelling example can be found in the realm of dental surgery. In a case where a patient required an intricate bone graft, a custom 3D printed surgical guide was developed following diagnostic imaging. This guide enabled the surgeon to accurately position the graft with exceptional precision. The patient experienced reduced swelling and a quicker return to normal activities, affirming the relevance of 3D printed surgical guides in improving recovery times and surgical outcomes in dental practices.

In the field of oncology, 3D printed surgical guides have made notable contributions to tumor resection. One case highlighted involved the removal of a tumor from a delicate region near the facial nerves. Utilizing a specially designed guide, the surgical team was able to navigate the anatomy with remarkable precision, thereby preserving vital structures while completely excising the tumor. This meticulous approach not only enhanced the surgical success but also significantly decreased the risk of complications, indicating the transformative potential of 3D printed technologies in complex surgical environments.

Furthermore, across various specialties, surgeons have consistently reported improved confidence and efficiency when employing these guides in preoperative planning and intraoperative navigation. As evidenced by these case studies, the application of 3D printed surgical guides not only raises the standard of care but ultimately benefits patient outcomes, paving the way for their future integration into routine surgical practices.

Future of 3D Printed Surgical Guides: Trends and Innovations

The landscape of surgical procedures is rapidly evolving with the advent of 3D printed surgical guides. As technology advances, it presents remarkable opportunities for enhancing surgical precision and personalization. One of the most significant trends is the increasing reliance on customization in surgical guides tailored to individual patient anatomies. Customized 3D printed surgical guides allow for a more accurate fit during procedures, leading to improved outcomes and reduced recovery times.

Another prominent development is the integration of artificial intelligence (AI) in the design and manufacturing of these surgical tools. AI can aid in analyzing patient data to create highly efficient and precise 3D printed guides, optimizing their design based on real-time anatomical information. This synergy between AI and 3D printing technology not only streamlines the design process but also enhances the overall efficacy of surgical interventions. As AI continues to evolve, it is anticipated that its application within the domain of 3D printed surgical guides will become more prevalent, leading to even more sophisticated solutions.

Furthermore, the implications of these innovations extend beyond the operating room. The healthcare landscape is on the brink of transformation as 3D printing technologies become integral in various medical applications, including education and training for surgeons, pre-operative planning, and even cost reduction in surgical procedures. As these 3D printed surgical guides become more accessible, it is expected that they will play a critical role in democratizing advanced surgical techniques across different healthcare settings, ultimately improving patient care.

In conclusion, the future of 3D printed surgical guides looks promising, with trends towards personalization through customization and the integration of AI. These advancements are poised to significantly shape surgical practices, making them safer and more effective, heralding a new era in patient-centered healthcare.

This is but the beginning of the journey. The future of 3D printed surgical guides holds very great promise. Researchers are working with increasingly advanced materials and coupling such guides with augmented reality for real-time surgical navigation.

3D Printed Surgical Guides: Revolutionizing Surgical Care

3D printed surgical guides provide an unprecedented degree of precision and customization and efficacy in surgery and can serve as a reshape of the current landscape of surgery. In fact, that innovative tool will help surgeons improve the care they deliver, and patients will view a better future for the health sector as a whole.