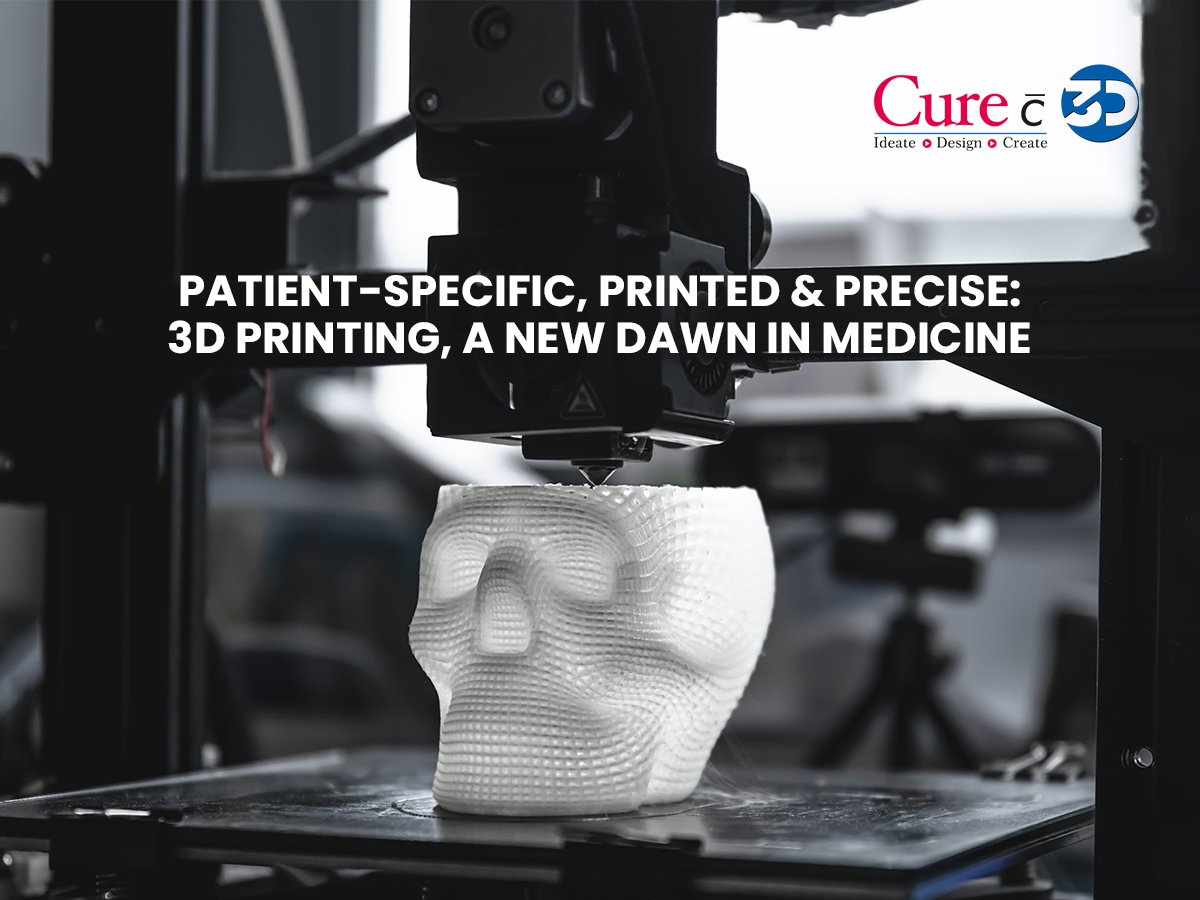

In 1981, when Dr. Hideo Kodama filed the first patent for a rapid prototyping system, it could not be imagined that what it was to usher in would be a medical revolution. Back then, the mere thought of creating a human body part by means of ‘printing’ was almost unreal. Now in the 21st century, 3D printing has transcended far from plastic prototypes & hobby creations. It now sits at the intersection of medicine & engineering, providing patient-specific healthcare solutions like custom human body anatomy models, 3D surgical jigs & 3D printed surgical implants.

And at the core of this evolution lies one powerful concept: personalization.

So, What is 3D Printing?

3D printing, aka additive manufacturing, refers to a method of making physical objects by laying down material in a layer-by-layer process, as specified by a digital model. It is a bit like playing with LEGO blocks, but instead of plastic blocks, you use different materials, ranging from more common plastic to metals like titanium.

In healthcare, the data from imaging data such as CT or MRI scans is used to create 3D anatomical models, patient-specific surgical tools, and implants.

How 3D Printing Works: The Core Technologies

Medical 3D printing uses several different technologies depending on the final application:

Fused Deposition Modeling (FDM)

Fused Deposition Modeling is used for building educational bone 3D models and prototypes of early designs in thermoplastic materials like ABS or PLA.

Stereolithography (SLA)

Offers high-resolution, smooth-surfaced models, this 3D printing technology is ideal for 3D printing anatomical models and intricate soft-tissue replicas.

Selective Laser Sintering (SLS)

Builds strong, functional surgical tools like 3D surgical jigs using nylon. This offers high durability and precision in the printed output.

Direct Metal Laser Sintering (DMLS)

Used for orthopedic implants and dental implants, offering excellent strength and biocompatibility with metals like titanium.

Providing Patient Specific Medical Care

No two patients exist identically, nor do their treatments. And that’s precisely what makes 3D printing increasingly irreplaceable in applications that require nothing less than pinpoint accuracy.

Human Body Anatomy Model for Surgical Planning

Surgeons today practice on 3D printed anatomy models. From advanced tumor resections to spinal corrections, they can practice procedures, anticipate potential complications, and improve outcomes.

Custom Surgical Implants and Trauma Implants

3D printed orthopedic implants and trauma implants reduce the risk of misalignment, infections, and recovery time. This is particularly valuable in implant surgeries involving irregular bone structures or prior trauma.

3D Surgical Guides and Jigs

Precision is everything in the OR. 3D surgical guides seek to assist with accurate screw, plate, or prosthetic placement while operating so that each incision counts.

Practical Uses of 3D Printing in Medicine

3D printing in medicine isn’t merely about equipment and consumables. It’s about ordinary people, everyday issues, and life-transforming answers. This is how different branches of medicine implement this technology:

Orthopedics

Surgeons today utilize 3D printing technology to manufacture customized joint replacements, prosthetics, even surgery jigs. The end result? Improved alignment, improved fit, and in most instances, patients with more successful recoveries.

Dentistry

Getting dental work done is changing fast. With 3D printing, dentists can now create implants, surgical guides, and full prosthetics in much less time. It also means fewer appointments and more comfort for the patient.

Trauma Surgery

In emergencies, every second matters. 3D printed trauma implants can be made quickly to match a patient’s exact anatomy. This helps doctors restore both form and function when time is critical.

Medical Education

Gone are the days when students only learned from flat textbook images. Now, future doctors and surgeons practice on realistic 3D anatomical models, making learning more hands-on and effective.

Right Material Matters in 3D Printing

The materials used for 3D printing depend on what is being 3D printed. For example, a surgical model may need flexibility, while an implant must be strong and safe for the body. Here are some materials that are employed for 3D printing

| Material | Technology | Best For |

| ABS & PLA | FDM | Educational models, demos |

| Photopolymer Resins | SLA | Soft tissue, vascular, or intricate visuals |

| Nylon | SLS | 3D surgical guides, jigs |

| Titanium | DMLS | Orthopedic implants, dental implants |

| PEEK & Bio-polymers | Advanced DMLS | Long-term, load-bearing medical implants |

What’s Next in 3D Printing in Medicine?

The journey to the future is full of potential, and some incredible things are as follows:

Bioprinting

Bioprinting is the process of 3D printing organs or tissues using bioinks. These bioinks are made of living cells mixed with thick, gel-like materials such as gelatin and alginate. These materials help the printed organ hold its shape and support the cells as they grow.

Mass Customization at Speed

As 3D printers become faster and smarter, making custom implants for the patient may take just a few hours.

Point-of-Care Manufacturing

Soon, hospitals might have their own 3D printing labs. These labs could make surgical models, emergency implants, or custom tools right when they are needed, without waiting for outside help.

The Future Is Being Printed Layer by Layer in 3D

From human body anatomy models to surgical implants that heal better and faster, 3D printing is rewriting what’s possible in modern medicine. What was once reserved for research labs is now transforming operating rooms, classrooms, and even emergency departments.

This is the quiet revolution in healthcare, precise, personalized, and printed.

The future is bespoke. Layer by layer. In 3D. With Curewith3D.