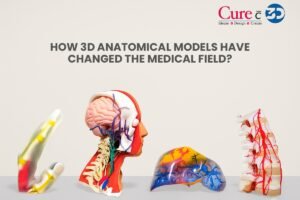

The medical education scenario is undergoing a sea change along with the fast-emerging scenario in the healthcare field. And among such technological innovations, 3D Printed Anatomical Models are a complete gem in the area of anatomical models. Such precise replicas have proved to be invaluable for surgeons, students, and researchers alike by offering hands-on study possibilities to study complex anatomical structures and procedures. Check the latest updates on 3D printing healthcare use on our website Curewith3D.

3D printed anatomical models represent a transformative advancement in the medical field, allowing for highly detailed replicas of human anatomy to be created with precision. These models are generated from medical imaging data, such as CT or MRI scans, and offer tangible representations of complex anatomical structures. The significance of 3D printed models lies in their ability to enhance medical education, improve surgical planning, and provide personalized patient care.

The evolution of 3D printing technology has significantly contributed to its adoption in medicine. Initially, 3D printing was primarily used for prototyping and industrial applications. However, as the technology progressed, its capabilities expanded into the healthcare sector. Today, various techniques, including Fused Deposition Modeling (FDM) and Stereolithography (SLA), are employed to create intricate anatomical models, catering to the diverse needs of medical professionals.

In anatomy education, 3D printed models serve as valuable teaching tools, enabling students and practitioners to engage with realistic depictions of human anatomy. These tangible representations facilitate hands-on learning and foster a deeper understanding of spatial relationships between different anatomical structures. Furthermore, 3D printed models aid anatomical visualization, which is particularly beneficial for students who may struggle with traditional two-dimensional images.

In the realm of surgical planning, the precision offered by 3D printed anatomical models allows surgeons to rehearse procedures based on patient-specific anatomy. This preparation enhances surgical outcomes by enabling better decision-making and reducing operative time. Similarly, these models contribute to personalized medical care, as healthcare providers can tailor treatments based on a patient’s unique anatomical variations. The increasing prevalence of 3D printed anatomical models in medicine underscores their importance and effectiveness in improving clinical practices.

Behind the scenes of these remarkable creations lies a fusion of cutting-edge technology and specialized expertise. Let’s take a closer look at the fascinating world of 3D Printed Anatomical Models and the driving forces behind their development.

Table of Contents

The Technology Behind the Magic

The core process in 3D printed anatomical model is additive manufacturing, a process that deposits layer by layer of material to build the three-dimensional object. It is this technology that makes possible accurate reproduction of even tiny anatomical details.

Different techniques are used, such as stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS). Different techniques render various advantages regarding resolution, material characteristics, or cost-effectiveness. These techniques enable models of human tissue texture, density, and elasticity to be produced close to that of the human operator handling it.

Expertise at Work

While technology provides a base, it is the vision of professional hands that gives life to 3D-printed anatomical models, as has been seen in the new designs we have just added to our website Curewith3D. Medical illustrators, engineers, and anatomists work together over every detail in order to ensure that the model shall be absolutely accurate and functionally informative, pooling their experience to tackle anatomical variations, surgical nuances, and educational objectives.

From presurgical planning patient-specific models to educational models aimed at improving learning outcomes, all these fall into the expert’s hands before shipping out. This attention to detail and dedication to excellence from these experts ensure that the anatomy in each and every detail is accurately reproduced and allows the user to experience the intricacies of the human body in a way hitherto unseen.

Advancing Healthcare and Education with 3D Printed Anatomical Models

The effects of the 3D printed anatomical models are profound and far-reaching beyond the laboratory or the operating room. These new tools may contribute to better patient outcomes, advances in surgical training, and breakthroughs in medicine. Giving surgeons real-life representation of a patient’s anatomy helps them visualize the approach they will take on a patient, prepares them for challenges that might be met, and optimizes procedural outcomes. For example, Curewith3D.

Similarly, hands-on practice of the anatomical models is beneficial to the students and professionals because there is a better understanding of anatomy, pathology, and surgical technique without fear of causing harm. Thereby, by assessing and perfecting their skills and confidence before entry in the operating room, the overall standard of care can be optimized as well as patient safety enhanced.

The Process of 3D Printing Anatomical Models

The creation of 3D printed anatomical models is a sophisticated process that begins with advanced imaging techniques such as Computed Tomography (CT) or Magnetic Resonance Imaging (MRI). These methods allow medical professionals to obtain detailed and precise images of a patient’s anatomy, providing a crucial foundation for the subsequent steps in the modeling process. The digital images generated by these imaging techniques serve as blueprints for building highly accurate anatomical representations.

Once the imaging phase is complete, the data needs to be transformed into a usable 3D model. This conversion typically involves software applications that can process the imaging data, convert it into a digital format, and create a mesh file that represents the anatomical structure. The segmentation of various anatomical features is also essential at this stage, as it allows for the customization of the model based on the specific requirements of a medical application. This customization can include modifying details such as size, shape, and even texture to match the intended use of the model.

After the creation of the 3D model, the next step is to select the appropriate printing technology. There are multiple techniques available, with Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) being among the most widely used. FDM works by extruding thermoplastic materials to build layers, while SLA utilizes a laser to cure photopolymer resins. SLS, on the other hand, employs a laser to sinter powdered material, binding it together to create a solid structure. Each technology has its own unique advantages, making it important to choose one that aligns with the specific requirements of the anatomical model being produced.

Materials Used in 3D Printing Anatomical Models

3D printing technology has revolutionized the creation of anatomical models, integrating various materials that enhance their accuracy, durability, and functionality. Among these materials, thermoplastics play a significant role. Thermoplastics such as PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) are widely used due to their ease of printing and adaptability. PLA, derived from renewable resources like corn starch, is non-toxic and provides excellent dimensional stability, making it suitable for producing detailed anatomical features.

Additionally, ABS is known for its strength and resilience, which are vital for models that undergo handling during educational or surgical training sessions. However, thermoplastics may not always provide the realistic appearance required for specific applications, leading to the exploration of other material options.

Resins have emerged as another preferred choice in the production of 3D printed anatomical models, particularly for high-fidelity representations. Photopolymer resins cure under UV light, allowing for exceptional detail and smooth finishes. This makes them ideal for applications where visual accuracy is paramount, such as in medical demonstrations or patient-specific surgical planning. Different resin types, such as flexible and high-temperature-resistant resins, can offer diverse characteristics suited for a variety of needs.

Furthermore, bio-compatible materials are increasingly gaining traction, especially in medical settings where models are intended for use in procedural simulations or patient interaction. These materials are designed to interact safely with biological tissues, thereby enhancing the training capabilities for healthcare professionals and minimizing risk in clinical environments. By selecting appropriate materials, manufacturers can ensure that 3D printed anatomical models not only meet specified accuracy metrics but also provide an authentic experience essential for medical education. Ultimately, the choice of material is critical for optimizing the realism and functionality of 3D printed anatomical models, tailored for specific medical applications.

Applications of 3D Printed Anatomical Models in Medicine

The advent of 3D printing technology has notably transformed the landscape of medical practice, providing innovative solutions through the creation of anatomical models. One of the most significant applications is in surgical training. Medical professionals are increasingly utilizing 3D printed models that reflect the unique anatomical features of individual patients. This allows for precise pre-operative planning and rehearsal, ultimately reducing risks during actual surgeries and improving surgical outcomes. By providing a tangible representation of complex anatomical structures, these models enable trainees and experienced surgeons alike to hone their skills through hands-on experience.

In addition to training, 3D printed anatomical models are instrumental in the development of personalized medical devices. These custom devices, tailored to the specific needs of individual patients, enhance treatment efficacy and comfort. For instance, models are used to develop orthopedic implants or dental prosthetics that match the exact contour of a patient’s anatomy, increasing the likelihood of successful integration and long-term satisfaction.

Furthermore, 3D printed models play a crucial role in patient education. Healthcare providers use these models to visually explain complex conditions and treatment plans, fostering a clearer understanding among patients. When patients can see and touch a physical representation of their anatomy, it often leads to improved patient engagement and collaboration in their healthcare journey.

Lastly, communication among healthcare teams is significantly enhanced through the use of 3D printed anatomical models. By providing a common reference point, these models facilitate discussions regarding treatment strategies and surgical approaches, promoting collaboration among surgeons, radiologists, and nursing staff. This multifaceted application of 3D printed anatomical models in medicine underlines their growing importance in enhancing both clinical practice and patient outcomes.

Benefits of 3D Printed Anatomical Models

3D printed anatomical models have emerged as a transformative tool in the healthcare sector, significantly enhancing the practices of medical professionals and the experiences of patients. One of the foremost benefits is the improvement in surgical outcomes. Surgeons can utilize these precise models to visualize complex anatomical structures before making incisions, aiding in pre-operative planning and reducing surgical risks. By aligning their surgical strategies with the unique anatomy of each patient, healthcare providers can deliver tailored interventions, enhancing success rates while minimizing complications.

Moreover, 3D printed models serve as powerful educational tools. They provide medical students and residents with tangible representations of human anatomy, fostering enriched learning experiences. Unlike traditional 2D images or textbooks, these models allow for interactive, hands-on learning, where students can explore various anatomical layers and conditions, thereby boosting their comprehension and retention of complex material. This hands-on experience is invaluable, equipping future healthcare professionals with the confidence and skills necessary for their careers.

Cost-effectiveness is another vital advantage associated with 3D printed anatomical models. While the initial investment may seem considerable, the long-term benefits often outweigh the costs. These models reduce the need for cadaveric dissections and the associated storage and maintenance expenses, offering a sustainable alternative for educational institutions. Furthermore, they can be produced on demand, minimizing waste and ensuring that resources are allocated efficiently.

Lastly, 3D printed anatomical models engage patients more actively in their healthcare journey. By providing customizable models that depict their specific conditions, these resources can significantly enhance patient understanding and compliance. When patients clearly comprehend the anatomical aspects of their health issues, they can make informed decisions regarding treatment options, resulting in improved satisfaction and outcomes. As such, the integration of 3D printing into healthcare serves as a crucial advancement, championing better results for both healthcare providers and their patients.

Challenges and Limitations in 3D Printing Anatomical Models

The production of 3D printed anatomical models is a promising field that offers numerous advantages in medical education and surgical planning. However, it is not without its challenges and limitations. One of the primary issues is the requirement for high-quality imaging data. Effective 3D printing of anatomical models relies heavily on accurate imaging techniques such as MRI or CT scans. Any deficiency in imaging quality can result in models that lack precision and detail, which are crucial for their intended use in diagnostics or surgical procedures.

In addition to imaging quality, regulatory hurdles pose significant challenges for the widespread adoption of 3D printed anatomical models. As medical devices, these models must comply with rigorous standards and guidelines set by regulatory agencies such as the FDA in the United States. The pathway for regulatory approval can be lengthy and costly, discouraging smaller companies or research institutions from pursuing development in this area. This regulatory complexity not only affects the timeline for bringing a product to market but can also limit innovation within the industry.

Potential inaccuracies in the models themselves represent another major challenge. Even with the best imaging data, 3D printing technology can introduce errors during the conversion of digital files to physical objects. Factors such as material selection, printer calibration, and the inherent limitations of the printing process can all lead to discrepancies between the model and the actual anatomy. As a result, it is essential for clinicians and educators to be aware of these limitations when utilizing these models.

Finally, the costs associated with advanced printing technologies cannot be overlooked. The initial investment for high-resolution printers, specialized materials, and personnel training can be substantial. These financial burdens may restrict access to 3D printing capabilities for many institutions, thus limiting the potential benefits of 3D printed anatomical models in various medical contexts.

The Role of Expertise in Producing 3D Printed Models

The advancement of 3D printing technology has significantly transformed the field of medical education and surgical planning, particularly in the production of anatomical models. However, the creation of reliable and informative 3D printed anatomical models is not solely reliant on the technology itself; it necessitates a collaborative approach that brings together diverse areas of expertise. The interplay between radiology, engineering, and surgical knowledge is fundamental in ensuring that the final product is both accurate and functional.

Radiologists play a critical role in this process by providing the necessary imaging data that informs the design of the anatomical model. Utilizing techniques such as MRI or CT scans, they generate detailed images of the anatomy, which serve as the foundation for model creation. Accurate imaging is essential, as it directly influences the quality and precision of the resulting 3D printed model. Any discrepancies in the imaging can lead to models that do not adequately represent the anatomical structures, which could impede educational objectives or surgical planning.

Additionally, engineers contribute their technical expertise to translate these complex images into tangible models. They employ sophisticated software to manipulate the data, ensuring that the 3D print accurately reflects the anatomical intricacies. Their knowledge of materials and printing techniques is crucial for optimizing durability and realism in the final models. In some cases, engineering innovations, such as the integration of flexible materials, may be essential for simulating specific anatomical features.

Finally, input from surgeons is invaluable, as their practical experience provides insights into the functional requirements of the anatomical models. Surgeons can guide engineers and radiologists in understanding which aspects of a model are critical for surgical training or preoperative simulations. This interdisciplinary collaboration fosters the creation of 3D printed anatomical models that are not only accurate but also highly functional, ultimately enhancing the educational experience and improving surgical outcomes.

Future Trends in 3D Printing Technology for Medicine

The landscape of 3D printing technology in medicine is rapidly evolving, with several emerging trends poised to shape the future of anatomical modeling. One significant advancement is the integration of artificial intelligence (AI) into the design and production processes. AI has the potential to enhance the precision and efficiency of 3D printing by automating model generation and optimizing print parameters. Through machine learning algorithms, AI can analyze patient data and create highly personalized anatomical models that cater to specific medical needs, thereby improving surgical outcomes and patient care.

Advancements in materials science are another crucial trend impacting the realm of 3D printed anatomical models. The development of new biocompatible materials is expanding the possibilities for the application of these models in various healthcare settings. Innovations such as flexible polymers and bio-inks enable the creation of models that more closely replicate the mechanical properties of human tissues. This capability not only aids in better surgical planning but also facilitates advanced training for medical professionals, allowing them to practice on models that closely resemble real anatomical structures.

Furthermore, the potential for fully customized solutions in healthcare is transforming how medical practitioners approach patient treatment. Additive manufacturing allows for the production of anatomical models tailored to the unique characteristics of individual patients. This customization extends across various medical fields, from orthopedics to cardiology, and enables doctors to visualize complex structures with unprecedented accuracy. As 3D printing technology continues to evolve, it is likely that we will witness an increasing integration of these trends, fostering a new era of personalized medicine.

Closing Thoughts on 3D Printed Anatomical Models

The evolution of 3D printed anatomical models marks a significant innovation in the medical field, providing unprecedented opportunities for enhanced education, surgical planning, and personalized patient care. Throughout this discussion, we have examined how these models enable practitioners to visualize complex anatomical structures with remarkable accuracy. This technological advancement not only aids in the training of medical professionals but also serves as an invaluable tool for patient communication and engagement. As the healthcare landscape continues to evolve, the integration of 3D printing technology has the potential to transform standard practices.

The versatility of 3D printing allows for the customization of anatomical models tailored to the specific needs of each patient. By creating patient-specific models, healthcare providers can engage in detailed preoperative planning, which can lead to improved surgical outcomes. Furthermore, these models facilitate more efficient training sessions for medical students and residents, providing them with tactile experiences that enhance their learning process. As such, the importance of 3D printed anatomical models in medical training and practice cannot be overstated.

Looking ahead, the future of 3D printed anatomical models in medicine appears promising. Advancements in materials science, printing technology, and imaging techniques will likely enhance the fidelity and feasibility of such models. As more healthcare institutions recognize the benefits of incorporating these tools into their practices, we can anticipate an increasing trend toward personalized medicine. This will herald an era where anatomical understanding is not merely a theoretical construct but an integral part of patient-centric care.

In conclusion, the potential for 3D printed anatomical models to revolutionize the medical field is immense. By improving anatomical understanding and facilitating tailored treatment options, these models can significantly enhance patient outcomes, ultimately reshaping the healthcare landscape for the better. As we continue to explore the applications of 3D printing in medicine, it is essential to remain attentive to the evolving technologies that will further refine our approach to patient care.

Conclusion

In the words of 3D printed anatomical models, technology and expertise meet, thereby transforming health care and education into a more developed state. As inspiration and profound insights from committed people arise from additive manufacturing, is it in these models alone that we can find unparalleled possibilities for learning, innovation, and patient care?.

Beyond that, looking to the future, only the continued evolution of 3D printing technology Curewith3D and the continued collaboration of this multidisciplinary team promises to further expand the option of anatomical models as opening up new possibilities for medical practice as well as discovery. Behind the scenes, the journey continues, driven by a shared commitment to excellence and a passion for advancing the frontiers of healthcare.